This high-speed paper cup forming machine, achieves a stable cup making speed of 120-130pcs/min and in the actual development test, the maximum speed can reach more than 150pcs/min. we reversed the previous design and redesigned a more optimized mechanical transmission and forming system. Whole machine main transmission parts are equipped with automatic spray oil lubrication system to reduce wear and tear. Its new designed open type intermittent cam system and helical gear transmission are more efficient and compact than those on old type MG-C800.Cup wall and the bottom of the cup are sealed with LEISTER bottom heaters imported from Switzerland . The whole cup making process is controlled and monitored by Delta inverter, Delta servo feeding, Delta PLC, Delta human-computer interaction touch screen, Omron/Fotek proximity switch, Panasonic sensor, etc., thereby improving the performance of the equipment and achieving fast and stable running. High degree of automation and automatic shutdown in case of failure to minimize the labor intensity of workers and achieve operational safety.

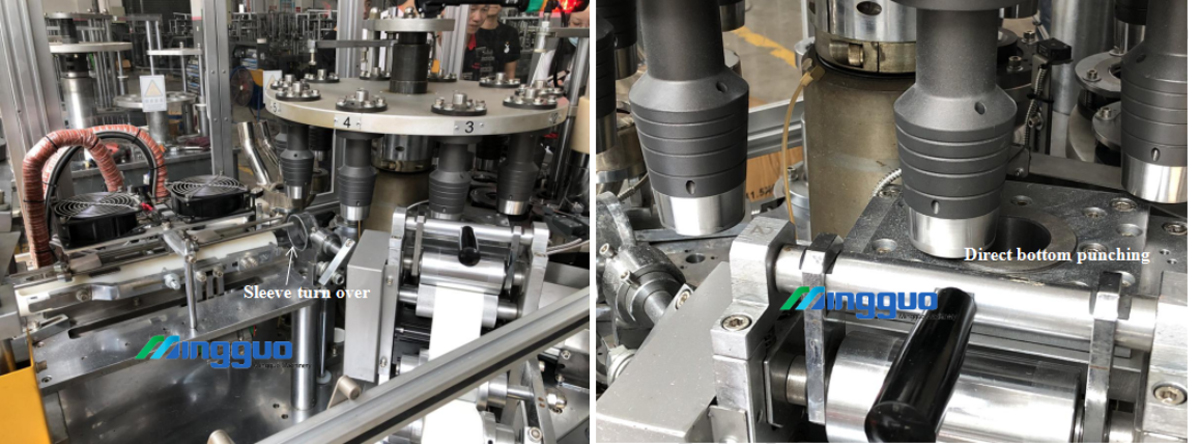

2. Direct paper cup bottom punching device controlled by Servo motor which is more accurate and paper-saving. 3. After punching the bottom, the cup molds with paper cup bottom will be transferred to accept the paper cup body sleeve. The sleeve will be turned over up and go through the molds.

2. Direct paper cup bottom punching device controlled by Servo motor which is more accurate and paper-saving. 3. After punching the bottom, the cup molds with paper cup bottom will be transferred to accept the paper cup body sleeve. The sleeve will be turned over up and go through the molds.  4. The molds with sleeve and bottom will be heated twice by the hot air guns. And then the end of the sleeve will be pre-folded inward to get ready for sealing with the paper cup bottom.

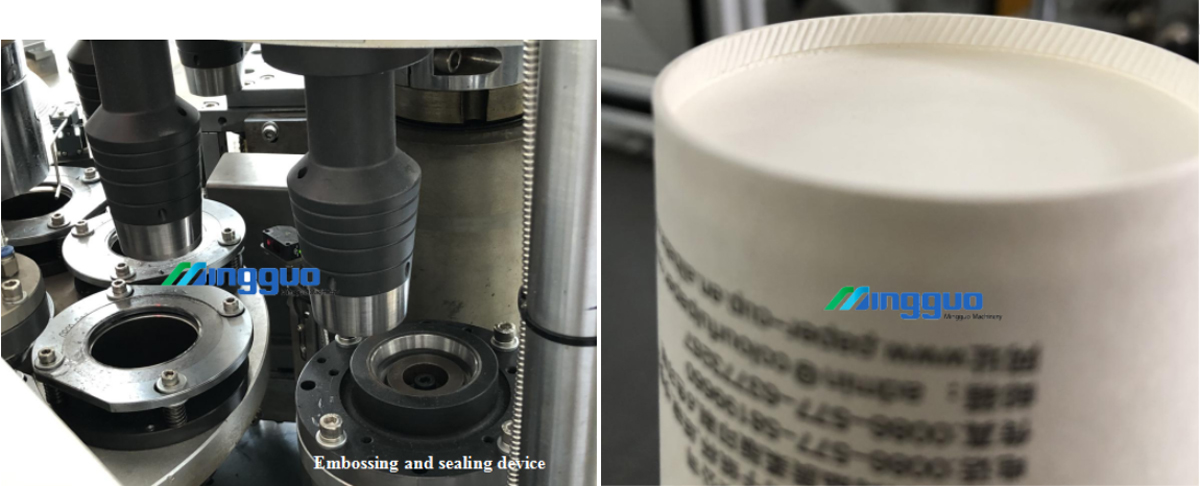

4. The molds with sleeve and bottom will be heated twice by the hot air guns. And then the end of the sleeve will be pre-folded inward to get ready for sealing with the paper cup bottom.  5. After the twice hot air gun heating and inward pre-folding, the paper cup bottom will be completely sealed well by the embossing and sealing device. Then the well-bottom-formed paper cups will be transferred to the Second turntable to form the top curling.

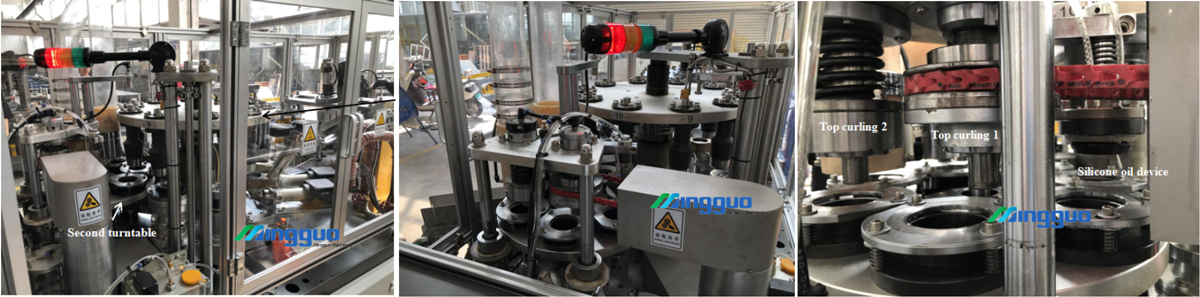

5. After the twice hot air gun heating and inward pre-folding, the paper cup bottom will be completely sealed well by the embossing and sealing device. Then the well-bottom-formed paper cups will be transferred to the Second turntable to form the top curling.  6. Before the top curling, the cup top will be moistened by the food grade silicone oil to make the curling top pressure well-distributed to avoid the burst, which will improve the paper cup aesthetic degree. 7. After the oil moistening, the cup top will be curled twice. Compared with once curling, twice curling is more suitable on high speed machine which makes the cup curling more compact and better-looking. To this step, a cup is done. The cups will be blown to the acrylic pipe to the collection table. Each stack quantity will be counted.

6. Before the top curling, the cup top will be moistened by the food grade silicone oil to make the curling top pressure well-distributed to avoid the burst, which will improve the paper cup aesthetic degree. 7. After the oil moistening, the cup top will be curled twice. Compared with once curling, twice curling is more suitable on high speed machine which makes the cup curling more compact and better-looking. To this step, a cup is done. The cups will be blown to the acrylic pipe to the collection table. Each stack quantity will be counted.